Turnkey Project of Palm Oil Mill Plant

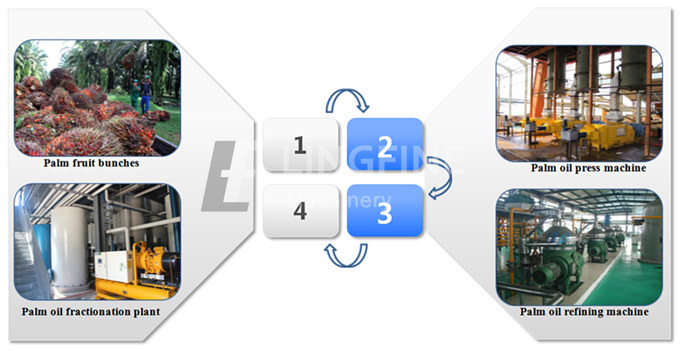

Our company is professional in manufacturing palm oil mill plant for years. We can offer the full palm oil production line and turnkey project.The complete palm oil mill plant includes palm oil pressing production line......

Turnkey Project of Palm Oil Mill Plant

Our company is professional in manufacturing palm oil mill plant for years. We can offer the full palm oil production line and turnkey project.The complete palm oil mill plant includes palm oil pressing production line, palm kernel oil pressing production line and palm oil refining production line.

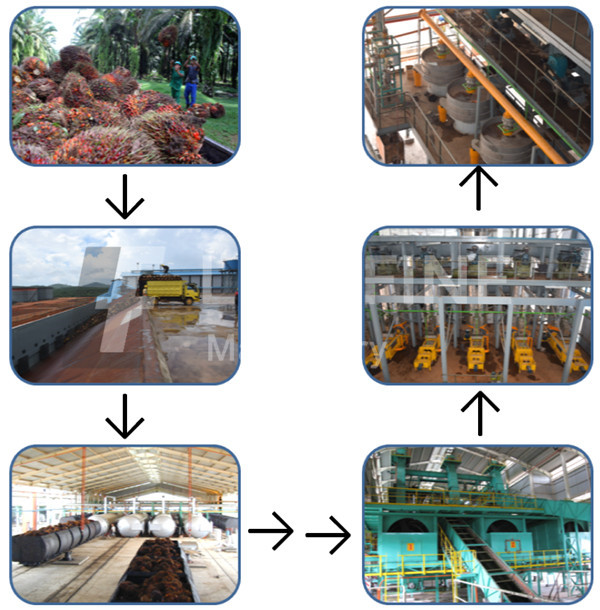

Production line of palm oil mill plant

Raw materials reception and storage

Workers pick fresh fruit bunches (FFB), transport them to palm oil mill plant with trucks, get the weight by weighbridge and discharge them to material platform which is specially designed for crude palm oil mill plant, laying up for later process. Open the gate of discharging platform, FFB would fall down to the conveyor automatically and be sent to sterilizing section.

Sterilizing section

The function of sterilizing, known as stewing in high temperature, is to avoid the deterioration of fruit. This sterilizing section in palm oil mill plant can avoid the increase of palm oil acid value by stewing the fruit about 60min with 300kPa steam in a specialized sterilizer.

Threshing section

The palm fruit proportion is about 60% of the FFB. In threshing section, we always use rotating drum thresher to separate palm fruit from the bunches.The separated oil palm fruit is ejected then into the crashing section. Empty fruit bunch be ejected to the yard from the other side of the revolving drum, or shipped out from the plant as palm orchards slipcover to recycling use, or burning in the locale as fertilizer for agricultural land.

Crashing

Before pressed, sterilized fruit must be re-heated to make the pulp soft and damage pulp cell structure. Crashing is the key equipment in palm oil mill plant which can ensure high oil yield.

Pressing

In crude palm oil mill plant, screw palm oil press is common equipment we use, the outcome of which is mixture of water, oil &residue and press cake (fiber cake).

Crude palm oil

Separate the fiber from the mixture derived from pressing by subsidence and filtration, after continuous subsidence we can separate oil and precipitate. With another filtration and vacuum drying, the oil is just crude palm oil as we say.

Palm kernel oil pressing production line of palm oil mill plant :

Palm kernel oil processing machine is another major equipment in palm oil mill plant. Palm kernel oil pressing production line can extract palm kernel oil from palm kernel. Main process are as follows:

Palm kernel oil press machine

1.Palm kernel Cleaning :Cleaning is a series of operation to remove impurities in oil seeds.It is used for removing the iron impurities, stone, fiber and others. These impurities are bad for palm oil mill plant, especial for the palm kernel expeller.

2.Palm kernel crushing: Because the palm kernel is hard and big size, it is required to crash to smaller and even pieces.

3.Palm kernel and nuts shell separation. Both dry and wet separations are available. Wet separation is mostly used in palm kernel separation, on basis of difference of relative density of palm kernel and shell.

4.Palm kernel drying. Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

5.Cooking section: It is used for heating and cooking the crashing materials, to make is suitable for palm oil mill plant , doing like this can help final user get the maximum oil and good quality cakes.

6.Palm kernel oil pressing. Palm kernel oil pressing production line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

7.Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.

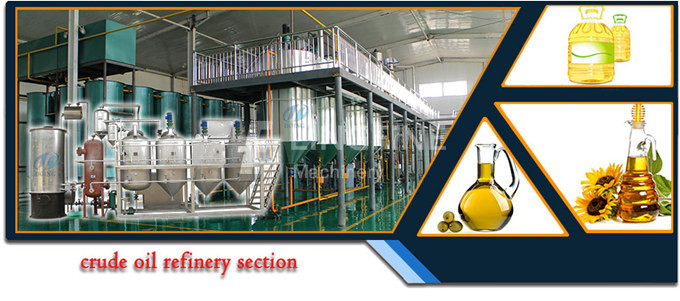

Palm oil refining production line of palm oil mill plant

Palm oil refining process is an essential process for a complete palm oil mill plant because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude oil.

Palm oil refining machine

The palm oil refinery plant work flow:

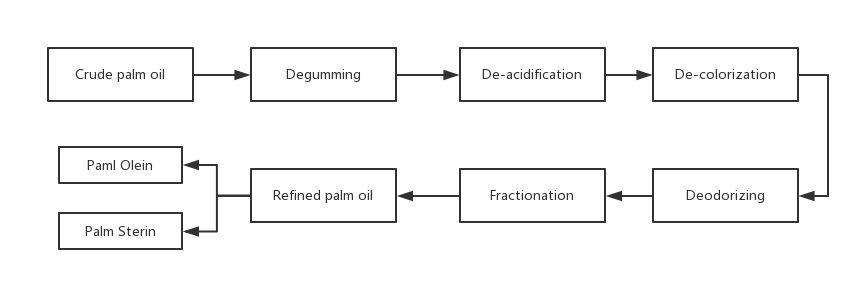

Crude palm oil and crude palm kernel oil refining process:

1. Degumming and De-acidification Section: Palm oil degumming and de-acidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refinery process.

2. De-colorization Section: Palm oil de-colorization section is mainly used to remove oil pigment, residual soap and metal ions during palm oil mill plant.

3. Deodorization Section: Palm oil deodorization section composes of part of crude palm mill plant. It plays important part in improving oil quality after crude palm oil process.

4. Fractionation section: Palm oil fractionation plant devides into 3 parts, crystallazing, crystall growing/maturing, and filtration. After palm oil fractionation plant, palm oil is separated to several parts with different melting points, which can be used in different industrial usages.

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!