Sesame Oil Pretreatment Machine

Sesame is an erbaceous plant widespread in Asia, Africa and India, where it’s by centuries a source of edible oil....

Overview

Sesame is an erbaceous plant widespread in Asia, Africa and India, where it’s by centuries a source of edible oil.

Sesame oil is yellow, with a typical and pleasant taste. In addition to the traditional food use, sesame oil find applications in pharmaceutical industry as vehicle of fatsoluble parental use medicaments (as some injectable hormons) and as mild laxative; for these use is necessary to have a sesame oil of very high quality obtained by cold pressing. Other uses are in cosmetic industry for the production of soaps and shampoos.

Sesame oil can be divided to 3 types, cold pressed sesame oil, hot pressed sesame oil, and solvent extracted sesame oil. As professional manufacturer of sesame oil plant, here we will introduce you sesame oil manufacturing process in details.

Sesame oil

Manufacturing Process of Cold Pressed Sesame Oil Mill Plant

After basic cleaning to remove impurities in sesame seed, simple oil cold press machine is needed to manufacture cold pressed sesame oil.

Sesame oil extraction machine

Manufacturing Process of Hot Pressed Sesame Oil Mill Plant

Same with cold press, cleaning is always needed to remove impurities in sesame seeds. After cleaning, sesame seeds are heated with direct fire to degenerate protein. Oil hot press machine extract oil from cooked sesame seeds at a high temperature. Comparing with cold pressed sesame oil, hot pressed sesame oil has special flavor which cold pressed sesame oil doesn't have.

Manufacturing Process of Solvent Extracted Sesame Oil Mill Plant

Solvent extraction is set of operation to extract sesame oil with very little oil residue, less than 1%.

As a leading manufacturer and supplier of oil processing equipment, our sesame oil processing plants have been exported to many countries and won good reputations all over the world. We can offer all equipment needed to manufacture sesame oil. If you are interested in sesame oil manufacturing, please feel free to contact us.

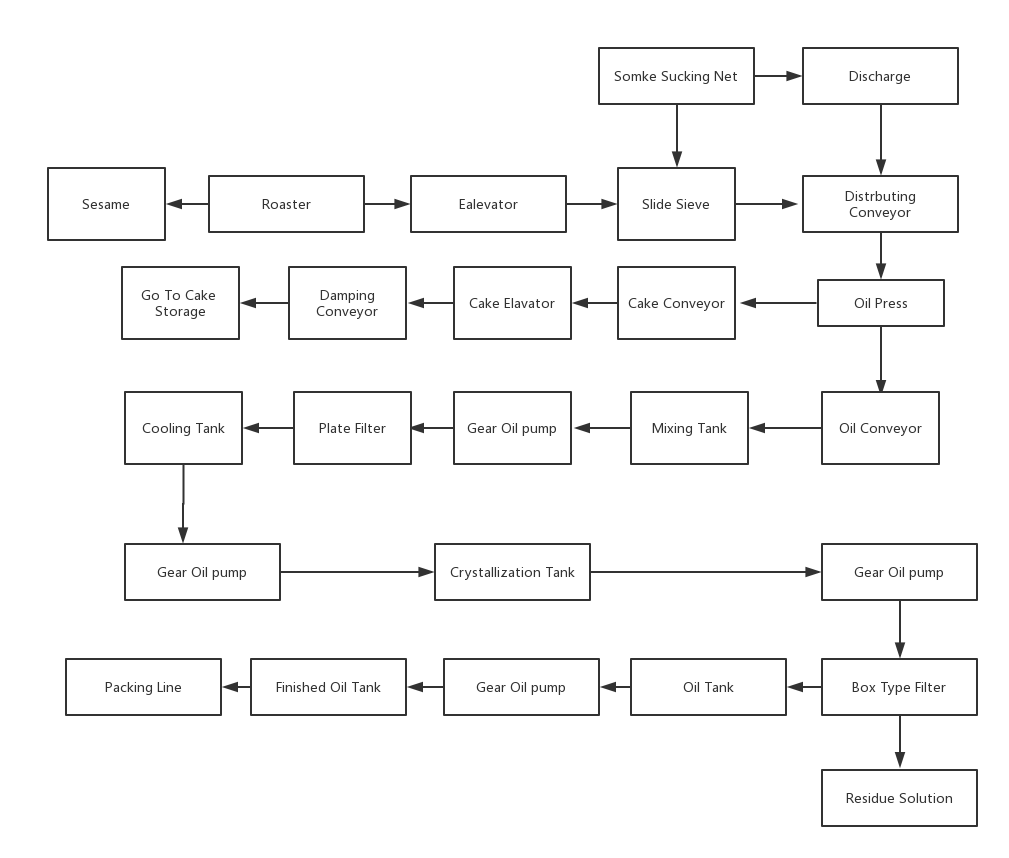

Process Flow Chart of Sesame Oil Mill Plant

Dry Type Cleaning

This process consists of 12 equipment to finish: winnowing, screening combination machine, stone removing machine, magnetic separator, dust screen, finish raw material feeding, winnowing, screening, stone removing, magnetic separation and the abstraction and discharge of the dust produced in this process.

Seed Hot Roasting

This process includes fuel delivery system, hot air furnace, seed roasting machine, fume collection equipment, hot air wind network, temperature detection system 7 units. After the quenching and tempering treatment, the raw material is uniformly roasted, which can ensure the sufficient denaturation and hardening of the protein in the raw material, and the whole process of the separation of the raw material and the waste gas produced during the process of seed roasting.

Oil Pressing

This process consists of nine equipment, includes thermal insulation conveyor. Modified special oil press machine, smoke removal device, cake conveyor equipment. Completing the whole process of extracting the oil from the sesame seeds, the transportation of the cake, and the extraction of the smoke by the oil press. To achieve the above procedures to fully treated raw oil, and best to ensure the quality of oil and operating environment to health.

Crude Oil Filtration

This process includes crude oil pool, crude oil pump, oil filter, oil pump etc, completing the whole process of suspending, filtration and transportation of the suspended matter in the crude oil.

Oil Sediment

This process includes oil pump, monitoring system, combined sedimentation tank, completing filtration of oil precipitation, producing the oil which meets the national standard.

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!