Rice Bran Oil Pretreatment Machine

Rice bran oil is the oil extracted from the hard outer brown layer of rice after chaff (rice husk). It is known for its high smoke point of 232 °C (450 °F) and mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying. ...

Overview

Rice bran oil is the oil extracted from the hard outer brown layer of rice after chaff (rice husk). It is known for its high smoke point of 232 °C (450 °F) and mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying. It is popular as a cooking oil in several Asian countries, including Bangladesh, Japan, India and China.

Rice bran oil has a composition similar to that of peanut oil, oil content of rice bran is about 16-22%. The rice bran is usually got in the rice oil mill factory. Because the technology of rice oil mill is different, the oil content of the rice bran also changes. The rice bran in different place is also different. No matter which kind of rice bran, it’s belongs to low oil content material. The best way for rice bran oil is solvent extraction way.

Brief Introduction of Rice Bran Oil Mill Plant

Type: Rice bran pretreatment, Rice bran expansion processing line

Processing Material: Rice bran

Processing Capacity: 5-1000T/D

Major Equipment: vibrating screen, stoner, magnetic separator, softening machine (conditioner), expansion machine, etc.

Application: High efficiency rice bran expansion, granulation for preparation of rice bran oil extraction.

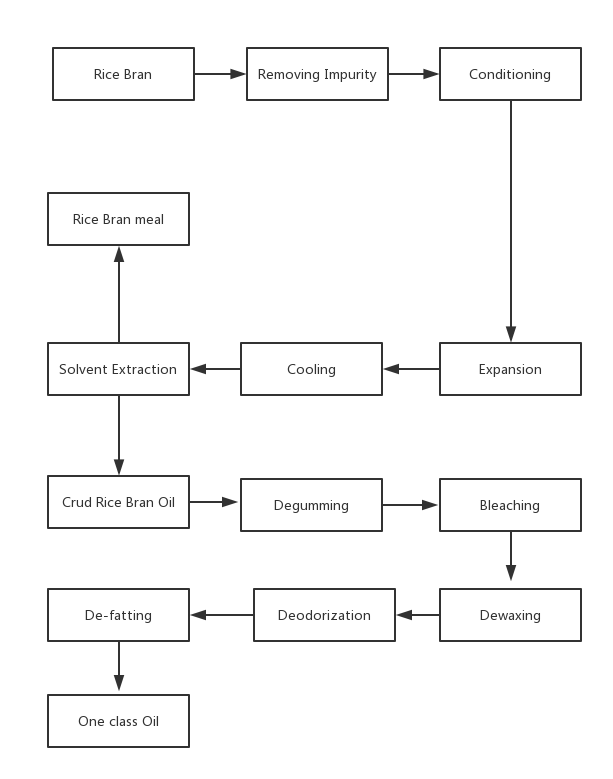

Process Flow of Rice Bran Oil Pretreatment & Expansion Plant

There are four main sections to make rice bran oil plant: rice bran pretreatment section, rice bran oil extraction section, rice bran oil refinery section and rice bran oil dewaxing section. The flow chart of rice bran oil processing plant is as following:

Brief Introduction of Rice Bran Oil Pretreatment Plant Machine

1) Magnetic: The first step is to move the iron in the rice bran, because the iron will harmful to the following machines.

2) Cleaning: After going through the cleaning sieve, the impurities in the rice bran will be cleaned.

3) Puffing machine/extrusion equipment: This is the special machine in rice bran oil pretreatment plant. This machine make the rice bran be to pellet. The pellet is easy for absorbing solvent and get oil by the solvent extraction way.

4) Dryer: After pellet making, the moisture of rice bran need be changed to 7-9%. This moisture is most suitable for solvent extraction section.

Rice Bran Oil Pretreatment Machine

Rice Bran Oil Pretreatment Plant Puffing Machine

Rice Bran Oil Solvent Extraction Plant

After the rice bran oil pretreatment machine, the cake will be sent to oil solvent extraction line and extracted oil by solvent. After get the crude oil, the rice bran oil can be sent to refinery line to get higher quality oil.

We can provide 5-2000T rice bran oil pretreatment/press equipment. According to your capacity and market, we will design the suitable line for you.

Working Principle of Rice Bran Oil Pretreatment and Expansion Plant

Rice bran oil expansion pretreatment will change the shape and structure of rice bran through press and promotion of non-isometric and nonstandard screw system of extruder. The gas among rice bran gap is squeezed out and quickly filled with materials, which causes rice bran sheared back and increased pressure inside the chamber. Rice bran hybrid is fully mixed, squeezed, heated, glued and pasted with increasing friction between screw and chamber, which changes rice bran structure and destroys rice bran fat layer structure.

At the same time, mechanical energy converts into heat, and machine chamber quickly rises to 125 degrees, which causes effective passivation of various enzyme activities of rice bran, and destruction of fat layer structure. The starch and protein turn into viscous state while rice bran is extruded to the exit, and high pressure changes into atmospheric pressure instantaneously. Moisture is evaporated from rice bran organizational structure quickly, forming into numerous pore structure inner rice bran.

Features of Rice Bran Oil Pretreatment Machine

High oil extraction rate and stable performance

High process ratio: Extracting part of oil from oilseeds of high oil-content ,creating a good condition for subsequent solvent extraction plant;

Unique design for each customer

Newest technology and automatic: Usually, our oil pre-pressing plant does not need extreme operating conditions.

The process technology of rice bran extrusion section can make the powder of rice bran become columnar structure of porous and good permeability, increase the density of rice bran, so that improve the seepage velocity of solvent, reduce residual oil of cake;

After puffing , extending the refreshing time of rice bran, greatly reducing the acid value, improve the quality of crude oil effectively;

The technology of rice bran extrusion is national patent product, perfect configuration, and it can meet international economic indicators.

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!