Mutton Tallow Making Machine

Tallow is a rendered form of beef or mutton fat. It is solid at room temperature. Unlike suet, tallow can be stored for extended periods without the need for refrigeration to prevent decomposition, provided it is kept in an airtight container to prevent oxidat...

In industry, tallow is not strictly defined as beef or mutton fat.

Mutton tallow machine, also known as mutton tallow cooking machine, mutton tallow refining machine, mutton production line, to get oil by extracting the sheep viscus and subcutaneous fat.

Mutton tallow, white or yellowish waxy solid with relative density 0.943-0.952. Melting point is 42~48℃. Is the fat extracted from sheep visceral and subcutaneous tissue, by boiling method preparation. It is used to make soap, stearic acid, glycerin, fatty alcohol, aliphatic amine, fatty acid, lubricating oil and so on. Fresh esters are refined and ready to be eaten.

LINGFINE uses the international advanced negative pressure mutton tallow making technology. Generally the whole mutton tallow production line includes the following sections:

Meat mincing, conveying, discharging, cooking, oil-slag separating, filtration, refining.

And the refining process includes: dephosphorization, degumming, deacidification, hydration, bleaching, deodorization etc. After treatment, the edible beef tallow made by our machine can be white snow color.

Below we will simply introduce you the production process of mutton tallow making plant:

Mutton Tallow Cooking Technology process

Process Parameter:

Residue oil in cake: About 20%

Moisture in cake: ≦ 6%

Impurity in crude oil ≦0.2%

Process Introduction

The production process of beef tallow includes: unpacking crushing section, preheating section, cooking section, dehydration section, oil-slag separating section, oil slag pressing section, crude oil filtration section etc.

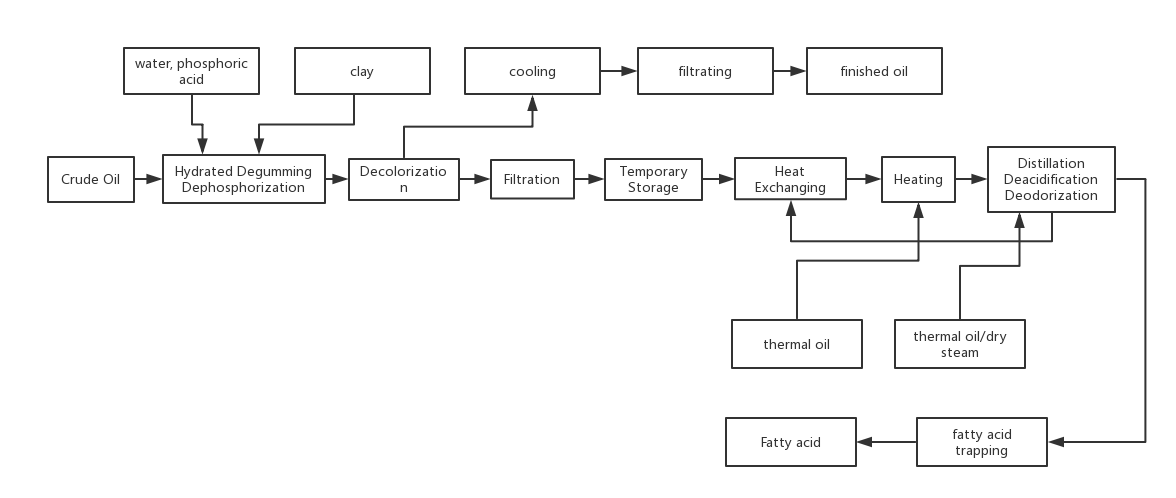

Mutton Tallow Refining Process

Crude mutton tallow refining process includes, degumming section, deacidification section, bleaching section and deodorization section. After refining process, the finished beef tallow can be edible.

Process Flow Chart

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!