Horizontal Feed Mixer

Feed mixer machine is a key step in feed pellet production plant due to its direct influence on quality of feed pellets. Feed mixer machines are performed to evenly blend various kinds of raw material powder and sometimes liquid adding equipments is necessary to be used to add liquid nutrition ing...

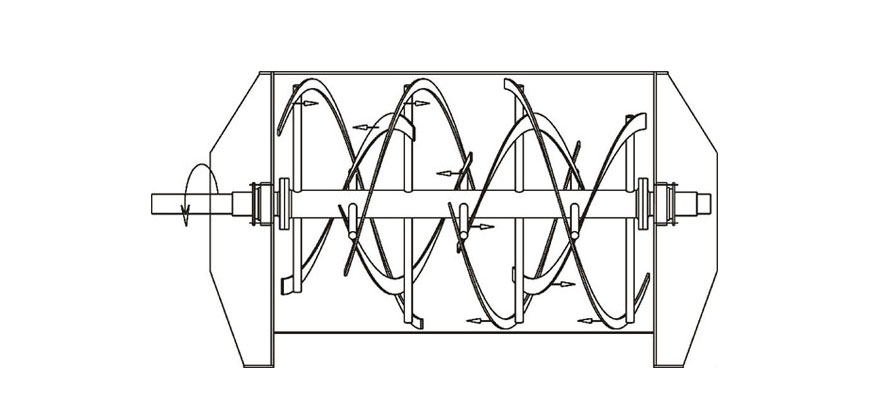

Feed mixer machine is a key step in feed pellet production plant due to its direct influence on quality of feed pellets. Feed mixer machines are performed to evenly blend various kinds of raw material powder and sometimes liquid adding equipments is necessary to be used to add liquid nutrition ingredients for better mixing. After highly mixing, the materials prepare the way for the production of high quality feed pellets. Our specially customized mixer machines enjoy popularity in the market.Mixing can improve the uniformity of particle sizes form hammer mill to keep them in the same particle hardness, which directly improve product quality. Therefore cattle feed mixer machine is the critical equipment in feed pellet production. cattle feed mixer with single shaft and twin-ribbon offered by our company, also named ribbon blender, is mainly applied to mix powdery feed materials to ensure a high quality of compound feed. And this poultry feed mixer is a well-performed feed mixer for fish and other livestock feed production plants.

Features of feed mixer

1. High homogeneity: this kind of single shaft feed mixer design reinforces convection, shearing, and mixing effects.

2. Moderate mixing and high uniformity, no segregation.

3. Human friendly: simple and reasonable structure, convenient maintenance, reliable, safe, effective and less investment. The feed mixer also can be equipped with jacket to facility heating and cooling materials. At the same time, thermal insulation materials also can be installed as required.

4. Multiple application: this cattle feed mixer can be used for mixing feed, food additives, binder, silicone rubber, pigment, printing ink, paraffin, resin, vanishing cream, ointment, detergent, etc; and also can be used for mixing viscous fluid and thick, pasty and granular materials.

5. Used for mixing of: powders with powders; powders with liquids

6. Large open layout, a quick feed, little residue, to meet the needs of adding the liquid.

Operation and Maintenance of Feed Mixer Machine

♦ After starting the mixer, check its running direction timely to avoid turning reversely.

♦ The load of the mixer must not exceed the effective volume.

♦ After using for 15 days for the first time, release the lubricant oil and clean the oil tank; change the lubricant oil in the speed reducer every three months, and fill grease to the bearing every two months.

♦ Minor repair of the mixer is needed after 1800 hours’ normal running, mainly to check the lubrication point or replace the wearing parts; overhaul is needed after 4000 hours’ normal running, mainly to disassemble to check and clean all the components, replace or rectify all the wearing parts and standard parts.

Specification of horizontal feed mixer

|

Model |

Power

(kw) |

Capacity

(kg/h) |

Size (mm) |

|

VTHS150 |

3 |

150kg/batch

5~8min/batch 600~800kg/h |

1550*850*1450 |

|

VTHS250 |

4 |

250kg/batch

10~15min/batch 800~1200kg/h |

2200*770*1530 |

|

VTHS500 |

5.5 |

500kg/batch

10~15min/batch 1000~1500kg/h |

2600*800*1700 |

|

VTHS1000 |

7.5 |

1000kg/batch

15~20min/batch 2000~3000kg/h |

2700*1150*1750 |

|

VTHS2000 |

15 |

2000kg/batch

15~20min/batch 4000~5000kg/h |

2800*2800*2000 |

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!