Fish Oil Making Machine

Fish oil is oil derived from the tissues of oily fish. Fish oils contain the omega-3 fatty acids eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA)....

LINGFINE uses the international advanced negative pressure fish oil making technology. Generally the whole fish oil production line includes the following sections:

Meat mincing, conveying, discharging, cooking, oil-slag separating, filtration, refining.

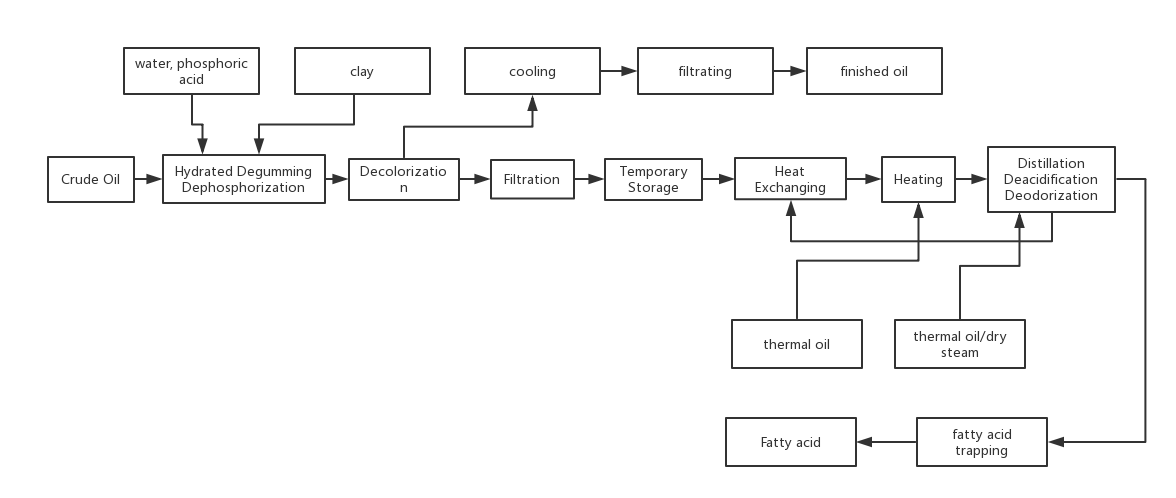

And the refining process includes: dephosphorization, degumming, deacidification, hydration, bleaching, deodorization etc. After treatment, the edible fish oil made by our machine can be white snow color.

Below we will simply introduce you the production process of fish oil making plant:

Fish Oil Cooking Technology process

Process Parameter:

Residue oil in cake: About 20%

Moisture in cake: ≦ 6%

Impurity in crude oil ≦0.2%

Process Introduction

The production process of beef tallow includes: unpacking crushing section, preheating section, cooking section, dehydration section, oil-slag separating section, oil slag pressing section, crude oil filtration section etc.

Fish Oil Refining Process

Crude fish oil refining process includes, degumming section, deacidification section, bleaching section and deodorization section. After refining process, the finished beef tallow can be edible.

Process Flow Chart

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!