Edible Sunflower Seed Oil Refining Machine

Refining technology: Chemical and Physical refining technology Processing capacity: 1ton to 600tons per day Raw material oil: any kinds of crude cooking oil, such as sunflower seed oil, soybean oil, palm oil, corn germ oil, sesame oil, groundnut oil etc...

Edible Sunflower Seed Oil Refining Line mainly contains the following sections:

Deacidification and Degumming, Decolorization, Deodorization and Dewaxing.

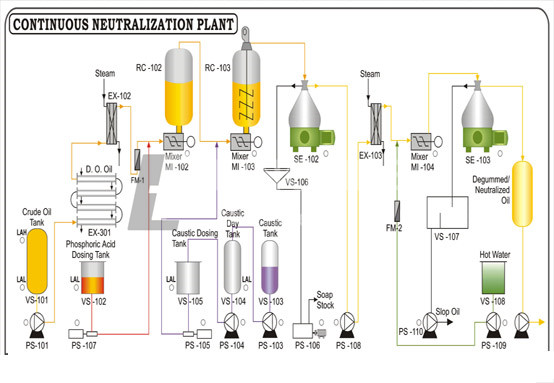

Deacidification and Degumming section of edible oil refining plant

The process of degumming also called dephosphorization remove colloidal impurities in oil . There are hydration, heating, adding acid and adsorption.

Degumming is to remove the peptizing impurities in crude oil,mainly to remove phospholipids, in addition to the phospholipid binding protein, saccharide, mucus, trace metals, etc.

Deacidification means removes the free fatty acids from the crude oil to lower the acid value of the oil. The deodorization processes commonly used by our company are Alkali Refining and Distillation methods.

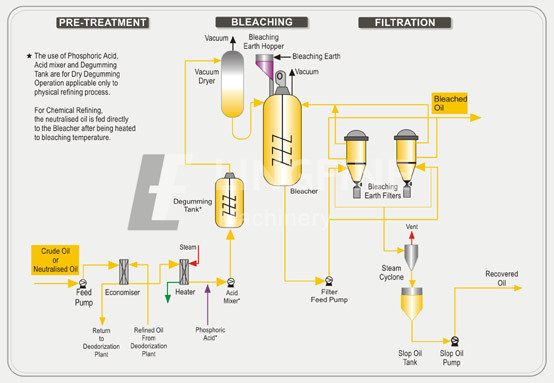

Decolorization section of edible oil refining plant

The main method we adopted is adsorption and bleaching (active clay).

The main process is adding high-activity clay into oil→ mixing ad heating in the state of vacuum→ making the small particle of pigment absorbed on the crystal of clay→ filtering the oil. Perfect mechanism, liable performance, well configured equipment of bleaching tower and the vertical leaf filter ensure the excellent bleaching and separation effect.

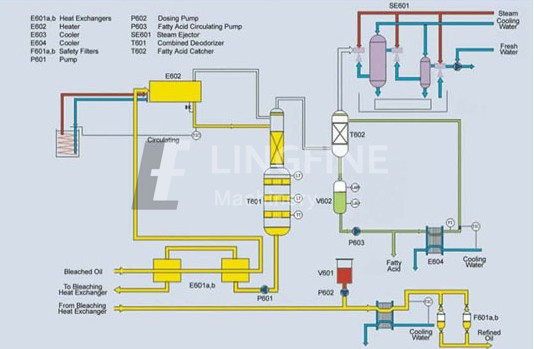

Common deodorization processes, scopes and characteristics

(1) Batch type deodorization process, it is used for the oil plants which process various raw materials with small production, but it has large steam consumption and it is difficult for heat recovery.

(2) Semi-continuous type deodorization process, it is used for the oil plants which frequently change oil varieties. Major processes are measure, de-gas, preheating, heating, deodorization, cooling. The time for changing raw material is short, and little residue is left; oil can outflow quickly; there is less external pipes besides deodorization equipment, so it is easy to clean and monitor. But the heat recovery is low, equipment costs are high and the steam consumption is large.

(3) Continuous type deodorization process, it is used for the oil plants which not frequently change the oil varieties. This process costs less energy and has a high ratio of heat recovery.

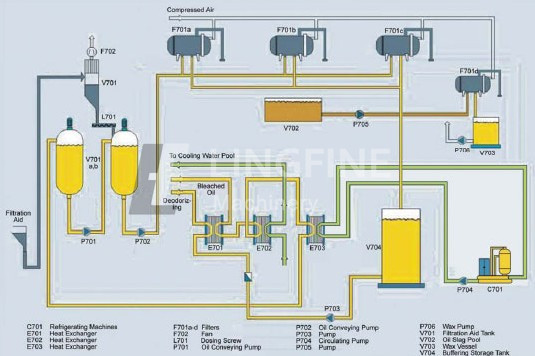

Dewaxing section of edible oil refining plant

It is necessary for the dewaxing process of corn germ oil, rice bran oil, sunflower seed oil, tea seed oil, cottonseed oil, flax seed oil and so on.

Dewaxing refers to the process of removing the high melting point wax from the liquid oil, preparing the salad oil, and improving the low temperature storage performance of the grease. Dewaxing is suitable for rice bran oil, sunflower oil and safflower oil containing waxy more vegetable oil.

Sunflower Seed Oil Grade I Standard GB10464-2003

| Index | Item | Standard |

| 1 | (Dispoable Cuvetes133.4mm) ≤ | Yellow 15 red1.5 |

| 2 | Smell & Taste | No smell & taste good |

| 3 | Transparency | Clear |

| 4 | moisture & volatile matters(%) ≤ | 0.05 |

| 5 | insoluble impurity(%) ≤ | 0.05 |

| 6 | Acid value(mgKOH/g) ≤ | 0.2 |

| 7 | Peroxide value(mmol/100g) ≤ | 5.0 |

| 8 | Smoke point(℃) | 215 |

| 9 | Residual solvent(mg/kg) | Not allowed |

Sunflower seed oil refining plant pictures

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!