Edible oil solvent extraction plant machine

Solvent extraction plant is a better way to extract oil from oil seeds, and after extracted, the oil residue rate will be only around 1%, which is suitable for the low oil content rate seeds....

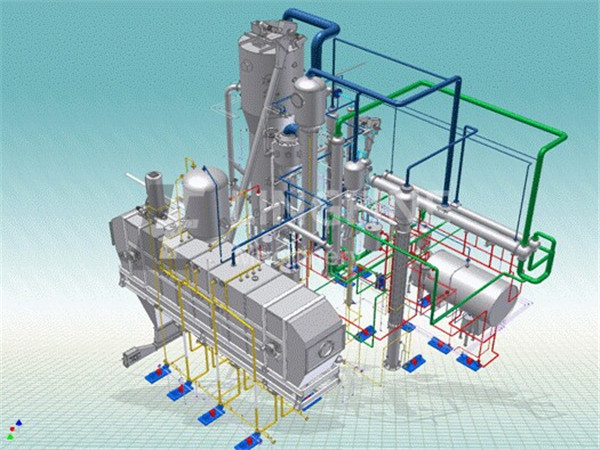

Oil solvent extraction plant

Solvent extraction plant is a better way to extract oil from oil seeds, and after extracted, the oil residue rate will be only around 1%, which is suitable for the low oil content rate seeds.

Solvent Extraction is a process involving the injection of Hexane into the oil bearing cells of seeds resulting in a mix of oil and solvent, the so called miscella. The Hexane will be evaporated later from the miscella resulting in unrefined oil. By condensing the Hexane it can be recycled and used over and over again.

Raw materials for edible oil solvent extraction plant

1, the pressed cake from the solvent extraction plant, such as the peanut cake, sunflower seed cake.

2, the oil seeds that can be extracted directly, such as the soybean, the rice bran.

Three methods for solvent extraction plant

Below 20t/day, we use batch type extraction tank unit.

From 20t/day to 600t/day, we use the Rotocel extractor.

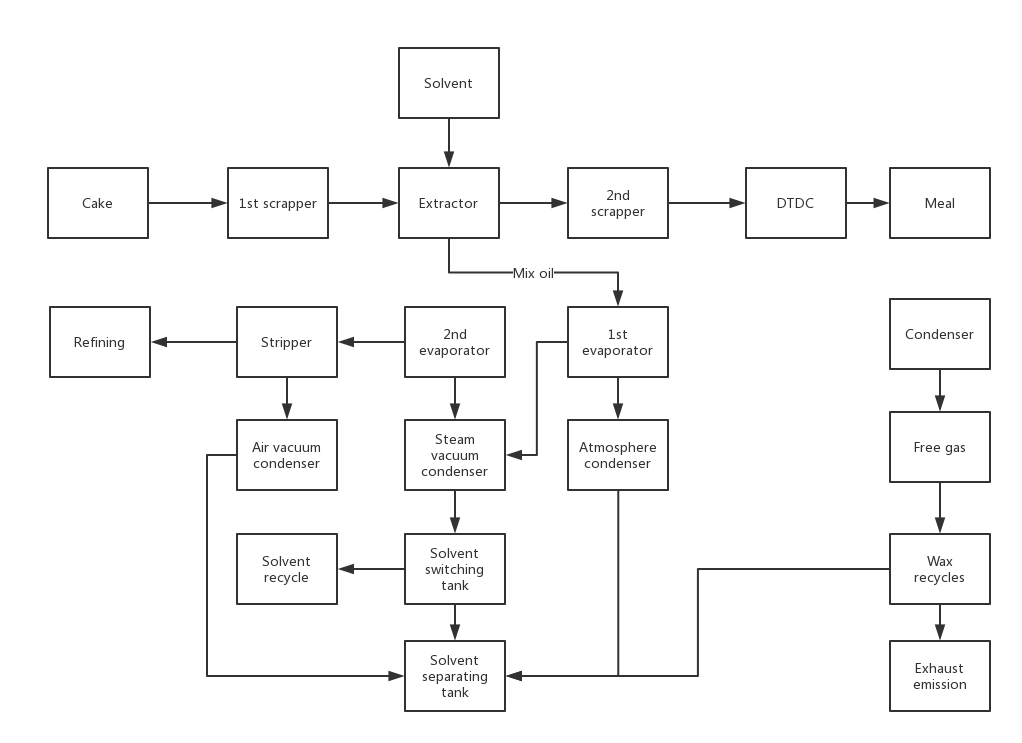

Edible oil solvent extraction plant processing flow chart:

The main systems of the solvent extraction plant

1, Solvent system of solvent extraction plant

The pre-pressed cake or flake, firstly enter into the sealed scraper blade to avoid the solvent gas escaping because of the section without screw blade in the sealed auger. Sunflower seeds enter into the box-chained loop type extractor counter-currenting with the solvent, the grease is extracted. Miscella condensity increase from 2% to more than 25%. Miscella discharged from extractor and into miscella filter, then the leached meal in the miscella tank enter into evaporation system through 1st evaporation feed pump and finally drop-in DTDC out from wet meal drag conveyor.

2, Evaporation process of solvent extraction plant

Using the secondary steam desolventized from DTC desolventizer and produced by steam-jet pump to heat and evaporate micella in the first long-tube evaporator. Export temperature reaches to 58-62℃ and condensity reaches to more than 65%. Then, micella enters into the second long-tube evaporator in which the temperature is heated to 105-110℃ by indirect steam and the condensity reaches to more than 95%. Then miscella enters into stripper in which residual solvent in oil will be removed, the export temperature reaches to about 105℃ and the general volatile of the extracted crude oil is less than 0.30%.

3,Desolventizing process of solvent extraction plant

Wet meals discharged from the bottom of extractor enter the top of DTDC and land on the predesolventizing trayers where they are heated by the indirect steam, thus, some solvent in meal is evaporated and meal temperature is risen; Predesolventized meals land on predesolventizing trayers where they use the second steam in desolventizing srayers to predesolventize solvent from meal, then, meals enter desolventizing layers in which direct steam is injected. Direct steam is sprayed into the meals through the bottom holes, and distill the solvent from meal by using steam in order to remove all solvent; Desolventized meals land on the following drying and cooling layer to dry and cool meals, cooled meals land on meal scraper blade from automatic material controlling gate on the bottom of cooling layer, and then they are entered into meal storehouse.

4,Condensation recovery process of solvent extraction plant

Extractor is equiped with a seperate condenser, 1st and 2nd evaporation share one condenser. Low and high temperature of solvent gas both from 1st and 2nd evaporation enter into the condenser after its neutralization, which greatly reduces the load of condenser and improves the efficiency of condensing. Stripping and analyzing share one condenser, the non-condensable gases from extractor and other condensers enter into the vent gas recovery system through the final condenser.

In the recycling system, the cold paraffin will absorb the solvent gas and the final nonsolvent gas will be discharged through fire resistance valve.Paraffin absorbed the solvent gas can be also called rich oil, after heating by oil-oil heat exchanger and steam, the rich oil will enter into desorber for desorption, and into condenser after changing solvent into gas, the final cooled paraffin can be recycled.

| Capacity | 10-500T/D |

| Residual oil in meal | ≤ 1% |

| Solvent consumption | ≤ 2Kg/T (No.6 solvent oil) |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Steam consumption | ≤ 280KG/T (0.8MPa) |

| Finished meal moisture | ≤ 13% (adjustable) |

| Residual solvent in finished meal | ≤300PPM (qualified detonated experiment) |

Main machines used in the solvent extraction plant:

(1). Solvent pumps: continuously spray solvent to the rotary-type extractor

(2). Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3). DTDC: used to separate the solvent from the wet meal.

(4). Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it.

The phospholipid and impurities in the miscella will react with the saline wter, at last the reactant precipitate, reaching the goal of purifying.

(5). Miscella tank 2nd: the purified miscella will be pumped into it.

(6). Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7). condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

As per safety regulations the main solvent extraction plant is located 50 ft. away from the Preparatory, Conditioning and Bagging section as highly hazardous and inflammable Normal Hexane solvent is used (50 feet is present prescribed distance around).

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!