Cottonseed Oil Pretreatment & Pre-pressing Machine

Cottonseed oil is a cooking oil extracted from the seeds of cotton plants of various species, cotton seed has a similar structure to other oilseeds such as sunflower seed, having an oil-bearing kernel surrounded by a hard outer hull; in processing, the oil is extracted from the kernel....

Introduction of Cottonseed Oil Plant

Cottonseed oil pretreatment & pre-pressing machine is ideally suitable to extract and produce oil from any kind of oil seeds such as peanut /groundnut, sesame, sunflower, cotton seed, rice bran, rapeseed, soybean, and palm kernel etc. Cottonseed oil pretreatment & pre-pressing machine adopts advanced crushing craft, automatic cottonseed oil prepressing machine, and corrosion-resistant body material design to achieve high quality grade cottonseed oil with low energy consumption and high efficiency.

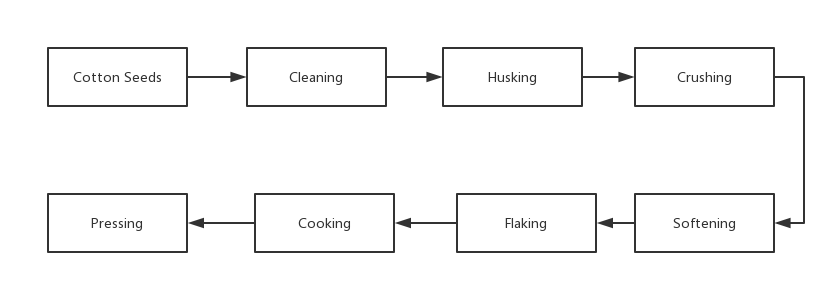

Process Flow of Cottonseed Oil Plant

Cottonseed Oil Pretreatment Process

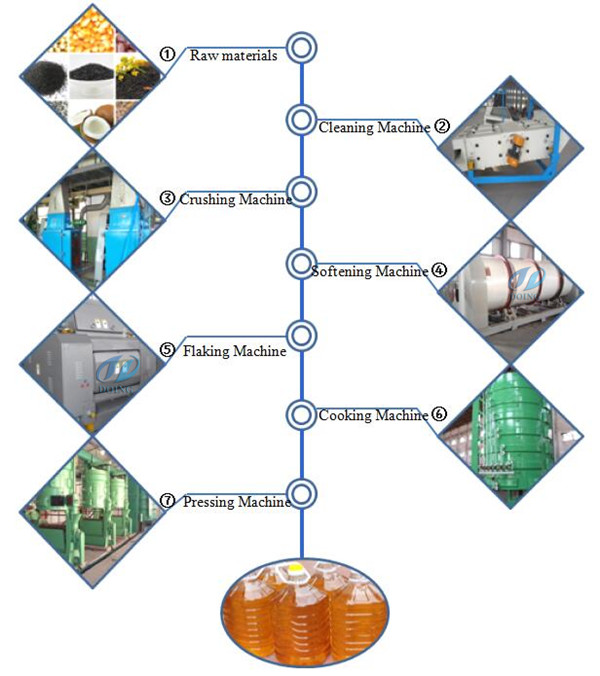

Main Equipment of Cottonsed Oil Pretreatment & Pre-pressing Machine

All these parts adjust temperature, moisture and form of cottonseeds to further extraction.

Cottonseed Oil Pretreatment Machine

1.Cleaning: Cleaning is a series of operation to remove impurities in oil seeds.

2. Husking/Dehulling/Shelling: Oil seeds like peanut, sunflower seed, cotton seed, palm kernel, etc, have hard shells above nuts. Husking/dehulling/shelling is to separate shells from nuts.

3. Crushing: Mechanical size reduction process is also named crushing. For big-size oil seeds, crushing reduces its size to benefit flaking, while for prepressed cake, crushing turns cake to proper size and creates better oil yield for second press or solvent extraction. Crushing is always necessary for soybean, peanut, palm kernel, coconut copra, cotton oil seed, etc.

4. Softening: Softening adjusts moisture and temperature of oil seeds, softens and increases plasticity of oil seeds. For low-oil-content oil seeds (soybean, rape seed/canola, cotton seeds, etc), softening is an essential process for better flaking effect. For example, oil content of soybean is 18-22%, while soybean is hard, low-moisture and low-temperature, flaking will bring plenty of powders without softening. However, this needs to be stressed that whether softening is needed still depends on the properties of oil seeds.

5. Flaking: Flaking presses oil seeds from granulous to laminar, which breaks cell tissue of oil seeds and creates beneficial condition for cooking. Flaking also makes oil flow out smoothly when pressing or solvent extraction.

6. Cooking: Cooking is to wet, heat, steam and to cook flakes to change the internal structure of flakes, including destroying cells, protein solidification and denaturation, etc. All these changes make oil easy to isolate and also enhance crude oil quality.

7. Pressing/prepressing: Pressing/prepressing is to press oil from oil seeds or cakes.

Cottonseed Oil Prepressing Machine

Function of Cottonseed Oil Pretreatment Production Line

1. Create a good production environment

2. Minimize the total oil loss, increase oil yield and output, also improve the quality of oil and cake meal.

3. Comprehensively utilize impurities and offal.

4. Perfectly match extraction production line, designing different production processes according to different oilseeds.

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!