Corn Oil /Maize Oil /Corn Germ Oil Pretreatment Machine

Corn oil (maize oil) is oil extracted from the germ of corn (maize). Its main use is in cooking, where its high smoke point makes refined corn oil a valuable frying oil. It is also a key ingredient in some margarines....

Overview Of Corn Oil

Corn oil (maize oil) is oil extracted from the germ of corn (maize). Its main use is in cooking, where its high smoke point makes refined corn oil a valuable frying oil. It is also a key ingredient in some margarines.

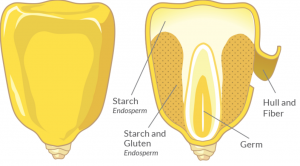

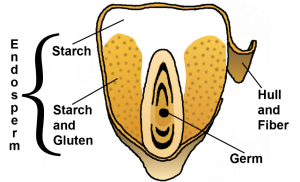

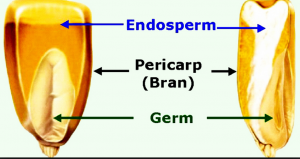

Maize germ is the raw materials of the oilseed press. There is germ 8-10 kg in every 100 kg of maize, pure germ oil 35 to 40 kg in every 100 kg, is double that of soybean oil content. The oil that squeezing from the corn germ is called corn oil, also called corn germ oil, corn oil or corn oil embryo is obtained. Usually we can see corn oil is yellow, transparent, with a fresh corn fragrance.

This oil contains linoleic acid about 57%, oleic acid 30% or so, also contains rich lecithin, minerals and vitamins A, D, E, and protein etc, its nutritional value is close to soybean, higher than peanuts, rapeseed and sunflower seed oil.

Lingfine company is professional in corn germ oil mill plant design, installation, trial run, technical training and so on. We can provide you turnkey project of the whole corn germ oil mill plant from 5 to 2000TPD. In general, corn germ oil mill plant divides to 3 section:

Corn Germ Oil Pretreatment workshop

Corn Germ Oil Extraction workshop

Crude Corn Germ Oil Refining Workshop

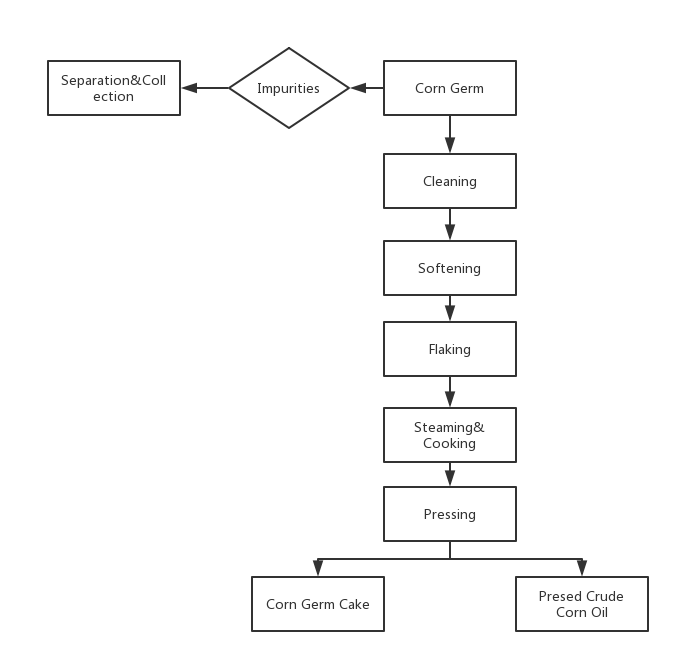

Production Process of Corn Oil Mill Plant

Almost all corn oil is expeller-pressed, then solvent-extracted using hexane or 2-methylpentane (isohexane). The solvent is evaporated from the corn oil, recovered, and re-used. After extraction, the corn oil is then refined by degumming and/or alkali treatment, both of which remove phosphatides. Alkali treatment also neutralizes free fatty acids and removes color (bleaching). Final steps in refining include winterization (the removal of waxes), and deodorization by steam distillation of the oil at 232–260 °C (450–500 °F) under a high vacuum.

Process Flow of Corn Oil Mill Plant

Main Process of Corn Germ Oil Mill Plant

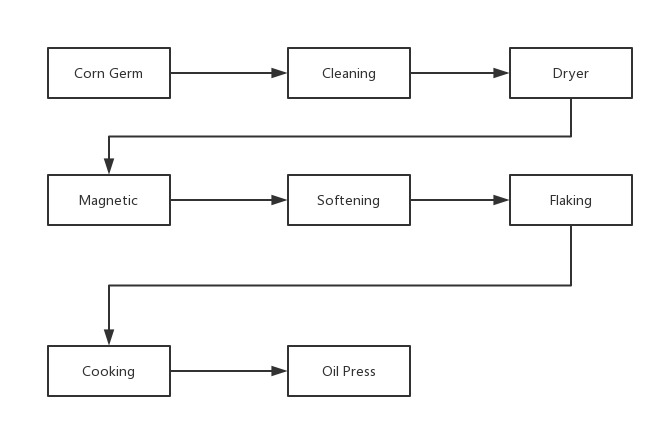

Following is a brief introduction about corn germ pretreatment/press plant:

1. Cleaning: This step is to move the impurities (peel, grits, flour, etc. ) in corn germ.

Cleaning Sieve

Dryer: The moisture of corn germ is about 15-20%. This step is to adjust the moisture of corn germ to 12-13%.

Magnetic: This step is to move the iron in corn germ, in case the iron might be harmful to the following machines.

Softening: This step is to adjust the temperature(to 50-60℃) & moisture(to 10%) of corn germ to get better flaking effect.

Flaking: After the flaking roller, the thickness of cake is about 0.4mm. The flaking roller helps to break the cell of corn and add the superficial area of the oil seeds. Then the oil is easier to extract.

Cooking: The cooker helps to adjust the moisture of the material to 6-8% and also adjust the temperature to 110℃, which also can improve the rate of oil production.

Oil press: 70% corn germ oil is extracted by screw oil press; while the oil content of the cake is 15-25%, which will be sent to leaching workshop.

Pretreatment section of the Corn germ oil production line is very important because it affecting extraction effect directly.

We can provide 5-2000T Corn Oil pretreatment/press equipment. According to your capacity and oil content of the corn germ, our professional engineers can design suitable line for you.

performace Features Of Corn Oil Mill Plant

Latest technology & professional design;

High oil yield & low waste;

Competitive price & quality

Stable performance:Corn germ account for about 8% of the whole corn in weight; 5. Create good production environment.

Minimize the total fat loss, increase oil yield rate and improve the quality of oil, cake and meal.

Comprehensively utilize impurities and offal.

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!