Animal feed pellet mill machine

The poultry feed pallet machine is widely used to produce feed pellets and biomass fuel pellets. Wide Application Range: Any kind of biomass materials containing wood fiber, such as peanut shell, bagasse, castor shell, straw, sawdust, coffee grounds, rice husk, sunflower shell, cotton stalk, tobacc...

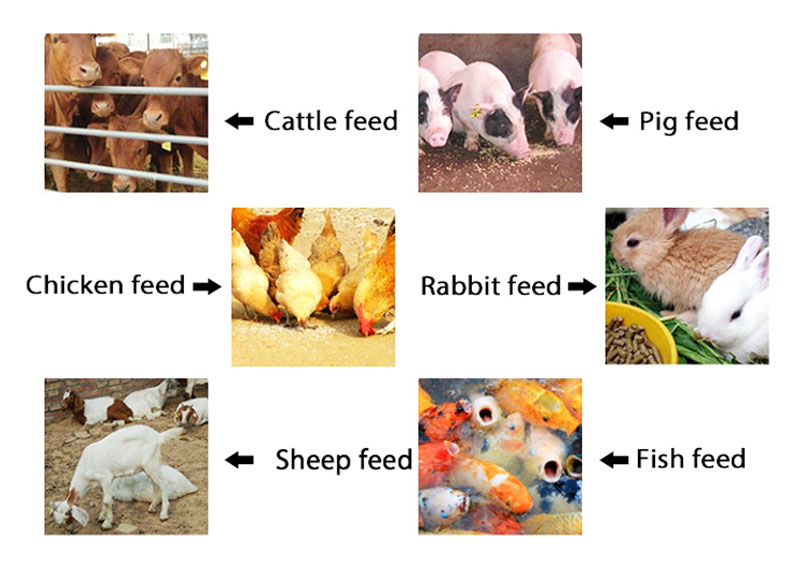

The working theory of feed pellet machine is that granulation is pressed out from the die hole under the extrusion of the roller pressure, the pellets length can be conveniently adjusted, and various of additive drugs can be added in the processed feed pellets, and the surface of the processed granule is smooth and clean. The hardness is moderate and the internal ripening degree is deep. Dry in dry out, easy to seal and store, natural temperature to 70-80 degrees can kill pathogenic microorganisms and parasites, and ensure feed quality, can be used to raise rabbits, chickens, ducks, geese, fish, pigs, aquatic products, etc.

Poultry Feed Pellet Making Process

animal feed making machine as explained earlier is a small and less complicated machine. This makes the processing of the pellets a bit easier to comprehend. The initial process is to bring the material for making the pellets. These includes soya bean meal, maize meal, vitamin among others.

this is the first step to ensuring all the large grains are crushed into powder forms. The chicken feed mill has a grinding machine that is specifically for the crushing purposes. Maize meals, broomcorn, wheat, beans, oilseed meal, soya bean meal may be in large grains and hence must pass the process. They are taken to the crushing machine where they are crushed into fine powder. Without this process, it might be next to impossible to make pellets.

Advantages Of Animal Feed Making Machine

It has a low production cost: The chicken feed machine does not require too many people to operate. In fact, it requires just one or two people to operate it. This greatly cuts the cost of labor that largely affects the production cost. Low production cost leads to increase in the profit margin.

Reduced installation cost: The chicken feed machine is simple and small hence it is easier to purchase and install it. You only need a few minutes to assemble the different parts. This reduces the amount of cash required to call a qualified personnel to assemble it. You only need one qualified personnel and another to help him.

It's a low investment machine: Due to its small size, the animal feed making machine requires a small area. This reduces the cost of hiring a big area of installing it and also the time required to install it.

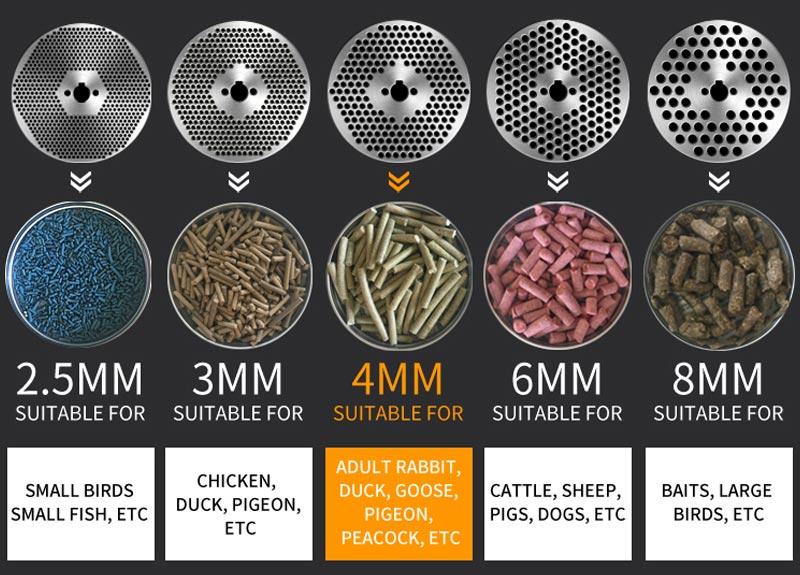

Has a wide application: The poultry feed machine is capable of producing different sizes of pellets for different poultry and livestock animals. This means you can feed all your animals using one machine at the same time. the poultry feed making machine has made it easier for the farmers to rear different types of animals in their farms.

| Feed Pellet Machine Parameter | ||||||

| Model | Capacity(KG/H) | Voltage(V) | Power(KW) | Weight(KG) | Dimension(MM) | Pressure Structure |

| LF-125 | 60-100 | 220/380 | 4.0 | 70 | 640*280*750 | 2 Wheel Type |

| LF-150 | 100-175 | 220/380 | 4.0 | 80 | 640*280*750 | 2 Wheel Type |

| LF-160 | 150-225 | 220/380 | 4.0 | 110 | 640*280*750 | 3 Wheel Type |

| LF-210 | 200-350 | 380 | 7.5 | 210 | 850*360*910 | 2 Wheel Type |

| LF-230 | 300-450 | 380 | 11 | 240 | 1070*420*1050 | 3 Wheel Type |

| LF-260 | 400-650 | 380 | 15 | 310 | 1070*420*1050 | 3 Wheel Type |

| LF-300 | 500-850 | 380 | 22 | 420 | 1300*510*1210 | 3 or 4 Wheel Type |

| LF-400 | 800-1550 | 380 | 30 | 800 | 1500*600*1800 | 3 Wheel Type |

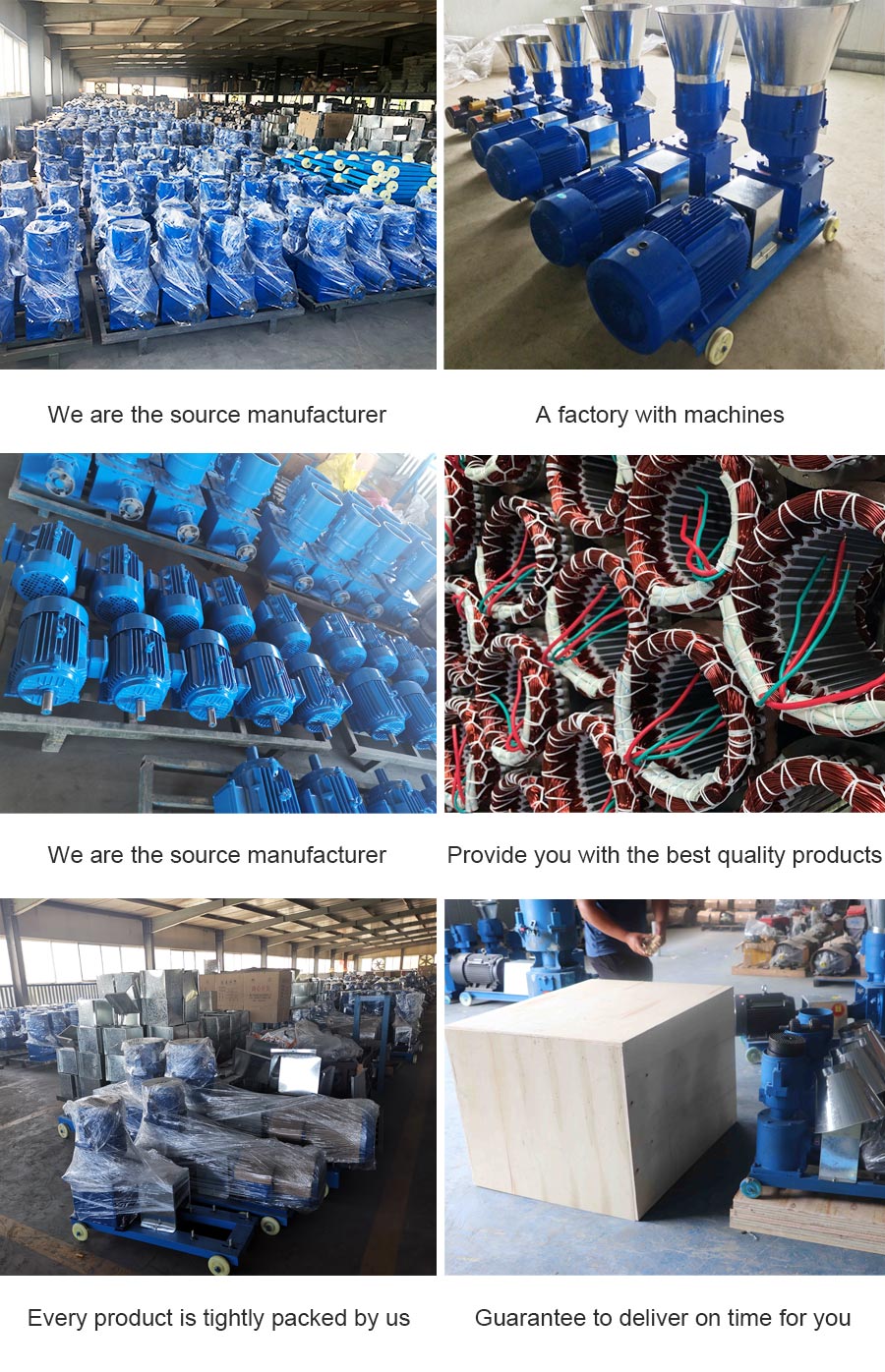

Factory show

Request a Free Consultation

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!